Topic 5 - Fusion Technology

As a new primary energy source with very low fuel consumption and globally abundant fuel resources, fusion has the potential to significantly contribute to meeting the globally rising demand for energy, safely and without CO2 emissions. The central projects of international fusion research are ITER and Wendelstein 7-X. ITER (tokamak configuration) will realize the world’s first “burning”, i.e., self-sustaining, fusion plasma. Wendelstein 7-X is the so far biggest and most important plasma experiment in stellarator configuration, has recently started operation at Greifswald. Fusion activities at KIT include most areas of fusion technology and low activation, neutron-resistant structural materials, as well as the development of key com¬ponents for ITER and a demonstration power plant (DEMO). The subtopics are microwave plasma heating, fusion magnets and magnet components, the deuterium-tritium fuel cycle, the breeding blanket, divertor technology for heat and particle exhaust, plant engineering including safety, remote maintenance and balance of plant, as well as structural materials for plasma vessel components, and fusion neutronics.

|

Integrated Fuel Cycle KIT has unique experience in designing, assessing, and operating the tritium systems which control and manage the fuel and product streams in Deuterium-Tritium fusion devices. The processes, crucial for the design and operation of fusion power plants, must be based upon well proven technology to assure the safe handling of tritium, to enable credible tritium accountancy and to provide high reliability of all components throughout the plant lifetime. Since more than two decades, KIT is taking the international lead in the development of key components for the fusion fuel cycle. |

|

|

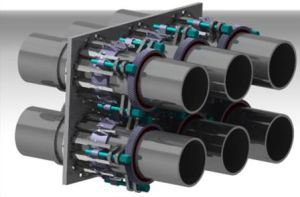

Microwave Plasma Heating A fusion power plant with an electric power of 1 GW requires the development of a Heating and Current Drive system capable to inject 50-150 MW into the fusion plasma. Since Electron Cyclotron Heating & Current Drive offers exact control and localized deposition of the radio frequency energy into the plasma, and hence is an important tool for plasma control and stabilization, it is a very important candidate heating system. KIT work, complemented by the work of other European Fusion Laboratories, is focusing on the RF Source (gyrotron), the microwave windows, and the launcher. |

|

|

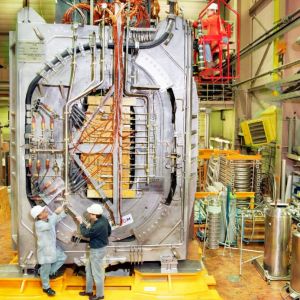

Fusion Magnets & Magnet Components KIT’s work for fusion magnets and magnet components is based upon the experience gained during the testing of the superconducting ITER Toroidal Field Model Coil. This forms the basis of our expert knowledge in magnet testing, cryo-genics, current lead design & construction, and high voltage & material testing under cryogenic conditions. KIT has designed and manufactured the high temperature superconducting current leads for W7-X and JT-60SA, and provides cryogenic material testing for W7-X, JT-60SA and ITER in the Cryogenic Material test facility Karlsruhe (CryoMaK). |

|

|

Plant Engineering This Subtopic comprises the R&D fields which concern DEMO/ fusion power plants as a whole, i.e., plant safety, plant logistics & remote maintenance, and balance of plant (BoP), which have interfaces with virtually all other plant systems, in-vessel components, and even the materials. Moreover, they will determine the viability and economic feasibility of a fusion power plant. KIT started its participation in these activities with the beginning of the coherent EUROfusion DEMO program in 2014. |

|

|

Breeding Blanket The Breeding Blanket is one of the key components of a fusion reactor; its primary functions are tritium generation in a nuclear reaction from fusion neutrons and 6Li to ensure tritium self-sufficiency of the reactor and heat removal at high temperatures for efficient electricity production. KIT covers the entire range of breeding blanket development, from conceptual design through the development of functional and structural materials and related manufact-uring technologies, to engineering design, safety analysis, and building and testing of mock-ups and prototypes. |

|

|

Divertor Technology The divertor is installed inside the plasma vessel and is exposed to extreme heat and particle loads as well as to the 14 MeV neutron flux from the fusion reaction. This makes the development of the divertor targets one of the most challenging tasks in the design of ITER and future power plants. KIT is working on technologies and materials both for helium-cooled and on water-cooled divertor concepts. |

|

|

Structural Materials for Blanket & Divertor The KIT expertise comprises the development of neutron resistant materials from the synthesis through comprehensive materials data bases and design rules up to fabrication and joining technologies. KIT developed the reduced activation ferritic-martensitic steel EUROFER, the European reference streel for ITER Test Blanket Modules and DEMO in-vessel components technologies. Also, new types of tungsten materials with enhanced ductility are under development. |

|

|

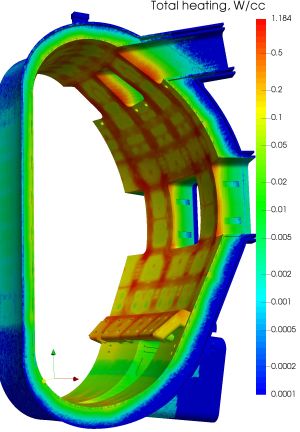

Neutronics Neutronics plays a fundamental role for the design and optimization of the nuclear components of a fusion reactor and the related performance evaluation. Particle transport and nuclear response simulations provide fundamental data like the Tritium Breeding Ratio, the nuclear power generation, and spatial distributions of the power density for the thermal and structural mechanical layout of the components. KIT’s activities in the neutronics field include nuclear analyses and modelling for ITER, fusion power plants, and the “International Fusion Material Irradiation Facility - Demo Oriented Neutron Source”. |